Sometimes, installing new wiring within walls or above ceilings isn’t the most practical or cost-effective choice. That’s where surface wiring comes in. It’s an easy, affordable way to add new lighting, switches, and outlets without cutting into existing walls. Here’s everything you need to know about planning and installing surface wires.

How Surface Wiring Works

Surface wiring mounts directly onto walls and ceilings. There’s no cutting, wire-fishing, demolition, or repair work required. Metal or plastic wireways connected with fittings protect and conceal the wires for safety and visual cohesion. Fixtures and devices get connected to the system through conduit boxes.

A few scenarios when you might prefer surface wiring include:

- Running low-voltage wires for speakers, coaxial, or Ethernet cables

- Adding electrical fixtures to finished rooms

- Upgrading electrical systems in older homes

- Installing wiring on concrete, brick, or block walls

Surface wiring isn’t a good choice for highly visible areas, extensive upgrades, or for creating an entirely new circuit. In those cases, you’re better off hiring an electrician to run wires the traditional way.

Surface Wiring Components

Product manufacturers sometimes sell surface wiring kits that combine in various configurations to make a complete surface wiring pathway. Components you might find in a kit include:

- Wireways: Various-sized channels made of plastic or metal that enclose and route the wires

- Conduit boxes: Places where wires connect to fixtures and devices

- Couplings: Fittings that join wireway sections together

- Elbows and corners: Fittings that allow the wireway to turn at 90-degree angles

- Other fittings: Tee connectors, end caps, and mounting clips stabilize the wireway

Planning Your Installation

Planning is crucial for a successful surface wiring project. Start by drawing a detailed diagram of your intended installation, especially where the new fixtures and outlets will go.

Next, is the product you have in mind easy to conceal? Or is it paintable? Being able to paint surface wiring makes it easy to hide. Also, is the new wiring self-anchoring?

Also consider where your power sources are. Connecting to an existing outlet or junction box is ideal. However, you must take into account the outlet’s load capacity. You don’t want to overload a circuit, something that can cause a fire or just cause the circuit to pop and shut off, ruining your project.

By measuring as accurately as possible, you’ll know exactly how much wireway material you’ll need. Have an electrician review the plan to make sure it’s both safe and doable.

You should also make sure you have the tools you need before starting. A full electrical toolkit may not be necessary, but you’ll definitely need a set of wire strippers, screwdrivers, a drill, and fasteners.

Step-by-Step Installation Guide

With planning complete, you’re ready to do the installation.

- Test the system. Make sure all connections are secure. Then, turn the power back on at the breaker and test the newly installed fixtures.

- Turn off the power. Cut power to the working circuit at the main breaker panel, and make sure nothing’s flowing by using a voltage tester.

- Access the wiring. Remove the existing cover plate and outlet to get to the wiring. Install a surface wiring starter box here that feeds power to the new wireway.

- Measure and cut. Measure the distance along your planned route, and use a hacksaw to cut wireway sections to the required lengths.

- Start placing fittings. Elbows and junction boxes help you route wireways more precisely and place new outlets. Use couplings to join each wireway section. Try to position each fitting where it’s least visible to minimize interruptions.

- Add anchors. Secure the wireway to the wall at least every 5 feet with anchors, screws, or other provided fasteners. Take care not to deform the wireway as you tighten the anchors.

- Install conduit boxes. At fixture and outlet locations, install surface-mount conduit boxes. Run wires from the boxes to the wireway, leaving 6 to 8 inches of extra wire at boxes to make connections.

- Install splice connectors. Use splice connectors to join wires together at splices and junctions. Follow the instructions on the wireway packaging and verify the wires are securely connected.

- Install your devices. Add switches, outlets, and light fixtures into the surface boxes and make wire connections.

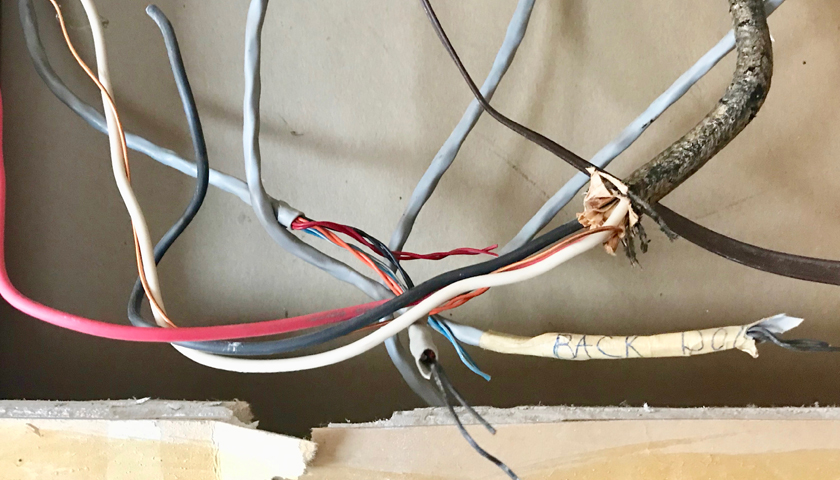

- Add labels. Consider labeling wires within the wireway for easier troubleshooting in the future.

Safety Tips for Surface Wiring

Surface wiring is generally safe when installed correctly. However, it’s still important to take these safety precautions and protect yourself:

- Turn off power at the breaker before starting work.

- Double-check wires are de-energized with a non-contact voltage tester.

- Follow product instruction sheets so wiring methods follow the manufacturers’ guidelines.

- Don’t overload circuits or draw more than 80% of a product’s rated capacity.

- Make sure all metal conduit boxes and wireway fittings are properly grounded.

- Use GFCI outlets in kitchens, bathrooms, laundry rooms, and other damp locations.

- Don’t install surface wiring in areas prohibited by local electrical codes, including some exterior locations.

- If your home uses aluminum wiring or if you feel uncomfortable handling any part of the process, hire a professional electrician.

Maintaining and Repairing Surface Wiring

Properly installed surface wiring requires minimal maintenance, but regular inspections can help you spot and prevent issues that may arise. Follow these maintenance tips:

- Periodically inspect wireways for damage, cracks, or deformities.

- Ensure cover plates on boxes and fittings are secure.

- Test GFCIs and AFCIs monthly by pressing the test and reset buttons.

- Gently vacuum surface wiring to remove dust, taking care not to damage wireways.

- Have an electrician inspect surface wiring every 3-5 years.

For repairs, such as fixing an electrical short, turn off the power at the breaker and identify the faulty component. Replace individual wireway fittings, boxes, or wire sections as needed.

In many remodeling and upgrade scenarios, it can save homeowners time, money, and disruption compared to traditional electrical work.

FAQs About Surface Wiring

Can I install surface wiring outdoors?

Most surface wiring components are intended for indoor installation only. Some exterior-rated wireways, boxes, and fittings are approved for outdoor use. Make sure any products you use outdoors are rated for wet exterior locations.

Does surface wiring require a special circuit breaker?

Surface wiring can be installed on standard, existing residential electrical circuits. It does not require a special circuit breaker.

What size wire is used for surface wiring?

Typically, surface wireways use 14- or 12-gauge electrical wire. Choose a wire gauge based on the electrical load.

Can I paint surface wireways?

Yes, painting them allows the wireways to blend into your home’s walls and ceilings. Be careful not to get paint inside the wireways.

Is surface wiring up to code?

Surface wiring meets electrical codes in many circumstances. However, specific installations may require a permit and inspection — research local requirements before beginning a project.